One Llodio Drive, Hermitage, PA USA 16148

How to Choose the Best Aerosol Can Manufacturers for Your Needs

Choosing the right aerosol can manufacturers is a critical decision for businesses operating in various sectors, including personal care, household products, and industrial applications. According to a recent market research report by Allied Market Research, the global aerosol can market is expected to reach USD 13.5 billion by 2027, growing at a CAGR of 3.9% from 2020 to 2027. This growth is driven by the increasing demand for convenient packaging solutions that enhance product functionality and consumer experience. As industries continually evolve, the importance of selecting reliable manufacturers becomes even more pronounced given the competitive landscape.

When evaluating aerosol can manufacturers, companies must consider several key factors, including production capacity, technological capabilities, and compliance with industry regulations. An in-depth analysis highlighted by Smithers Pira emphasizes that manufacturers who prioritize sustainability and innovation are more likely to succeed in meeting the diverse needs of their clients. Additionally, with consumers becoming increasingly environmentally conscious, partnering with manufacturers that demonstrate commitment to eco-friendly practices can provide a significant competitive advantage. Thus, understanding these dynamics and making informed decisions about aerosol can suppliers will be indispensable for achieving business objectives in this robust and expanding market.

Identifying Your Specific Aerosol Product Requirements

When selecting the right aerosol can manufacturer, it's crucial to first identify your specific product requirements. Consider the type of aerosol product you need—whether it's for personal care, household cleaning, or industrial use. Each category has unique specifications that may influence your choice in materials, propellant types, and can designs. Be clear about your intended application and the desired performance characteristics, such as pressure, spray pattern, and durability. This foundational understanding will greatly facilitate your discussions with potential manufacturers.

Tips: Begin by creating a comprehensive list of your requirements, detailing aspects like volume, safety features, and environmental considerations. This will not only help streamline your search but also enable you to communicate effectively with manufacturers.

As you delve deeper into your requirements, consider industry standards and any certifications that may apply to your product. Understanding regulatory compliance is essential, particularly in sectors where safety and quality are paramount. Inquire about a manufacturer’s experience with materials that comply with environmental regulations, as this can impact both the efficacy and acceptability of your product in the market.

Tips: Conduct thorough research on manufacturers’ certifications and quality control processes to ensure they meet industry standards. This diligence will pay off in the long run by ensuring a reliable and safe aerosol product.

Choosing the Right Aerosol Can Manufacturers Based on Product Requirements

Researching the Manufacturer's Industry Reputation and Experience

When selecting the best aerosol can manufacturers for your specific needs, the manufacturer's industry reputation and experience should be your top priority. An established manufacturer often indicates a commitment to quality and reliability. It is crucial to research their history, looking into how long they have been in the industry and their track record with past clients. A company with extensive experience is likely to be well-versed in compliance standards and possess valuable know-how related to production processes.

Tips: Check online reviews and testimonials from previous customers to gain insights into their service quality. Participate in industry forums to hear firsthand accounts of experiences others have had with the manufacturer. Additionally, consider reaching out directly to ask about their certifications and quality assurance practices, as this can provide assurance of their commitment to industry standards.

Furthermore, understanding the manufacturer's specialization can help assess if they can meet your specific aerosol needs. Some manufacturers might excel in producing certain types of aerosol cans, while others may have a broader range but less depth in specific applications. Engaging directly with potential manufacturers can also reveal their openness to collaboration and customization, which is essential for fulfilling your unique requirements.

Tips: When discussing with manufacturers, inquire about their R&D capabilities, as innovation is often a good indicator of a manufacturer’s responsiveness to market demands. This not only ensures you receive a product that meets current standards but also positions you better for future development.

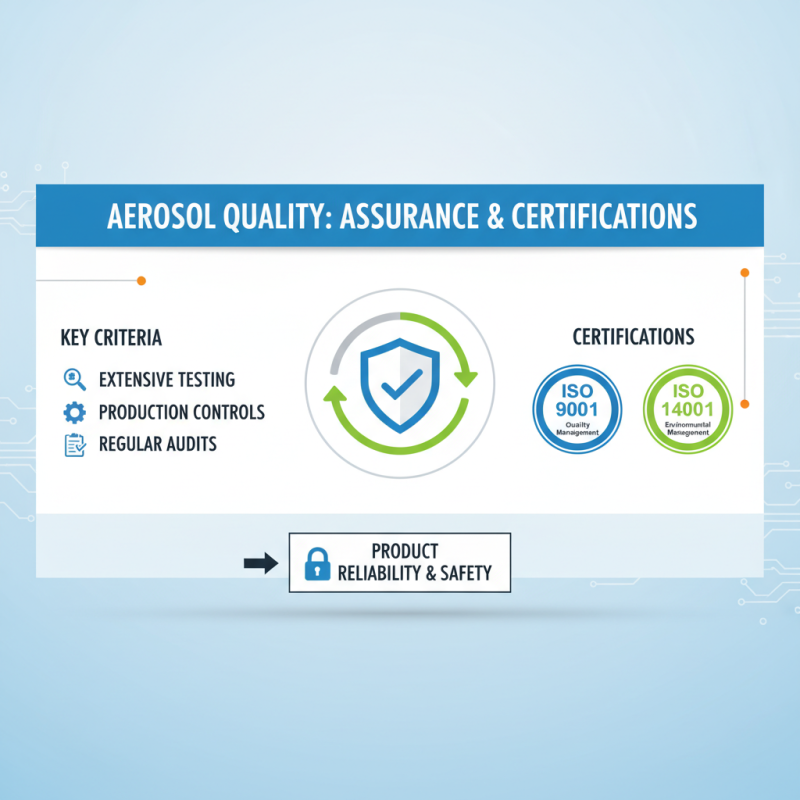

Evaluating Quality Assurance Processes and Certifications

When selecting aerosol can manufacturers, evaluating their quality assurance processes and certifications is crucial to ensure that the products meet your specific criteria for safety and performance. A robust quality assurance system typically encompasses extensive testing protocols, production controls, and regular audits. Look for manufacturers that adhere to internationally recognized standards such as ISO 9001, which emphasizes quality management systems, or ISO 14001 for environmental management. These certifications indicate the manufacturer’s commitment to maintaining high quality throughout their production processes, which can significantly affect the reliability of the aerosol products.

Additionally, it’s essential to examine the specific quality assurance measures they implement during production. This includes checking materials for compliance with safety standards, performing rigorous product testing, and having a transparent process for handling defective products. Manufacturers that engage in continuous improvement practices, such as Six Sigma or Total Quality Management (TQM), demonstrate a proactive approach to quality that can reassure you of their capability to deliver consistent and safe aerosol can products. By prioritizing these factors, you can make informed decisions that align with your operational needs and safety standards.

Comparing Pricing Structures and Minimum Order Quantities

When selecting an aerosol can manufacturer, understanding their pricing structures and minimum order quantities (MOQs) is essential. Pricing can vary significantly based on the type and complexity of the cans, including factors such as materials used, customization options, and production methods. Manufacturers may offer tiered pricing based on order volume, which means that larger orders often come with reduced per-unit costs. Therefore, it is crucial to communicate your budget constraints and production needs up front to receive the most accurate pricing information.

Minimum order quantities can also play a critical role in your decision-making process. Some manufacturers might set high MOQs to ensure production efficiency, while others may offer more flexibility, allowing you to place smaller orders. If your business is just starting or you require diverse product lines, opting for a manufacturer with lower MOQs can be advantageous. However, balancing this against the cost per unit is vital to ensure that your overall expenditure aligns with your business goals. By carefully assessing these factors, you can identify a manufacturer that meets your specific needs while maintaining cost-effectiveness.

Assessing Customer Service and Support for Long-Term Partnerships

When choosing an aerosol can manufacturer, assessing customer service and support is crucial for establishing a long-term partnership. A reliable manufacturer should demonstrate responsiveness and a proactive approach to customer inquiries and concerns. This includes providing clear communication channels, such as dedicated account managers or support teams, to ensure that clients feel supported throughout their collaboration. Timely feedback can make a significant difference in product development, helping to resolve any issues that may arise and facilitating a smoother manufacturing process.

Additionally, effective customer support goes beyond mere responsiveness. It encompasses the manufacturer’s ability to offer technical assistance, guidance during the design phase, and solutions to potential challenges. A good partner will listen to your specific needs and provide tailored advice, ensuring that the final product aligns with your expectations. Moreover, assessing their willingness to engage in continuous improvement and to invest in relationship-building can indicate their commitment to your long-term success. This collaborative spirit is essential for navigating the complexities of production and ensuring that both parties thrive in the partnership.

How to Choose the Best Aerosol Can Manufacturers for Your Needs - Assessing Customer Service and Support for Long-Term Partnerships

| Manufacturer Type | Customer Support Rating | Response Time (Hours) | Technical Support Availability | Long-Term Partnership Score |

|---|---|---|---|---|

| Standard Manufacturer | 4.2 / 5 | 24 | Business Hours | 80% |

| Specialty Manufacturer | 4.5 / 5 | 12 | 24/7 | 85% |

| Eco-Friendly Manufacturer | 4.0 / 5 | 48 | Business Hours | 75% |

| High-Volume Manufacturer | 4.8 / 5 | 8 | 24/7 | 90% |

| Custom Solutions Manufacturer | 4.6 / 5 | 16 | Business Hours | 88% |

Related Posts

-

10 Best Aerosol Packaging Solutions for Eco-Friendly Products in 2023

-

Top 10 Benefits of Aluminum Bottle Packaging for Eco-Friendly Brands

-

What is Packaging in the Pharmaceutical Industry? Understanding Its Importance and Innovation

-

How to Choose the Best Aerosol Filling Companies for Your Business Needs

-

What is a 16 oz Aluminum Bottle and Why You Need One Today

-

Why Aluminum Bottles Wholesale are the Best Choice for Your Business Needs